News

News Industry News

Industry NewsCommon dust sensors (also called PM2.5 sensors) on the market are divided into two categories: infrared dust sensors and laser dust sensors. Whether it is an infrared principle or a laser principle dust sensor, it can be used to measure the concentration of particulate matter in the air. What is the difference between the two? It can be compared from the following aspects:

Structure and principle

Infrared dust sensor

The structure of the dust sensor based on the infrared principle is relatively simple. Its light source is an infrared LED light source. According to the principle of light scattering, the light emitted by the LED encounters dust to produce reflected light. The photosensitive detector detects the intensity of the reflected light and judges the concentration of dust according to the size of the pulse signal. When no dust is detected, the photosensitive detector outputs a low pulse; conversely, when dust is detected, it outputs a high pulse.

Laser dust sensor

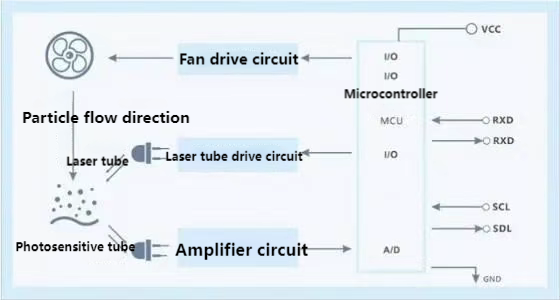

Unlike the dust sensor based on the infrared principle, the laser dust sensor has a fan that can generate a stable airflow. Once it is started, it can quickly obtain the PM2.5 concentration value in the current environment.

Because the laser dust sensor uses a laser LED as a light source, its structure and circuit are more sophisticated than the infrared sensor. When fine particles in the air are pushed into the area where the laser beam is located by a constant current fan, the laser will be scattered. We place a photodetector at an appropriate position so that it only receives scattered light. Then, the photoelectric effect of the photodetector generates an electrical signal. After circuit amplification, the concentration value of the fine particles can be obtained.

Measurement accuracy

The infrared light source used by the infrared dust sensor has a long wavelength (about 700~900nm), and the measurement accuracy of particles with aerodynamic diameters less than 1um is insufficient. Because the particle signal scattered by the infrared LED light is weak, it only has a relatively obvious response to large particles larger than 1um, and only uses a heating resistor to drive the sampling airflow, the sampling number is small, and the measurement accuracy is about ±30%.

The laser sensor can detect dust particles as small as 0.3um. Because it has a higher performance MCU, a constant speed fan is used to increase the air intake, and higher density data is collected, the overall measurement accuracy can be achieved. ±10%. Therefore, the laser dust sensor has obvious advantages in sensitivity, accuracy, and consistency over the infrared dust sensor in terms of measurement accuracy.

Application scenario

Due to insufficient accuracy, infrared principle sensors are mainly used for industrial and mining dust, and the detection objects are large-particle size and high-concentration dust, and the concentration of PM2.5 cannot be accurately measured.

Laser principle sensors are mainly used in the field of PM2.5 detection, quantifying PM2.5 quality with high precision, and can be embedded in household (car-mounted, handheld) air detectors and air purifiers. In addition, laser principle sensors are also used in the fields of IoT data collection and environmental quality detection.

Tensensor's laser dust sensors are divided into different series according to different fans and air inlets and outlets. They are widely used in dust detectors, purifiers, fresh air systems, smart homes, air conditioners and other fields. If you are interested, please contact us for more information:

ShanXi TengXing Sensor Technology Co.,Ltd

Web: www.tensensor.com

Email: [email protected]

Tel/WhatsApp: 86 18335818384