News

News Industry News

Industry NewsThe air around us contains numerous colorless and odorless gas molecules that have a significant impact on human activities. From toxic gases (such as CO, H₂S, and SO₂) generated during industrial production processes, to pollutants (such as NO₂ and O₃) used in environmental monitoring, to oxygen and carbon dioxide in daily life, accurate detection of these gases remains a crucial issue for safe production, environmental protection, and health management. Among numerous gas detection technologies, three-electrode electrochemical gas sensors, with their high sensitivity, excellent selectivity, and low power consumption, have become one of the most widely used.

Basic Principle: From Fuel Cells to Gas Sensing

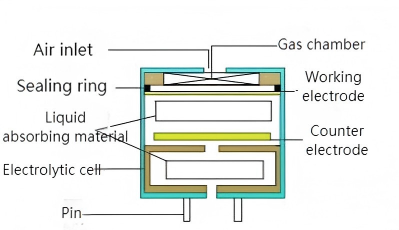

The basic principle of electrochemical gas sensors originates from fuel cell technology. At its core, they consist of an electrochemical cell filled with an electrolyte and isolated from the outside environment by a gas-selective permeable membrane. When target gas molecules diffuse through the membrane, oxidation or reduction reactions occur on the surface of the sensing electrode, generating a current signal proportional to the gas concentration.

Taking carbon monoxide (CO) detection as an example, its typical electrochemical reaction is:

Working electrode (WE): CO + H₂O → CO₂ + 2H⁺ + 2e⁻

Counter electrode (CE): 1/2O₂ + 2H⁺ + 2e⁻ → H₂O

Design Advantages of Two- and Three-Electrode Systems

Early electrochemical sensors used a two-electrode design (working electrode and counter electrode). However, this structure has significant drawbacks: the counter electrode serves the dual roles of providing a current loop and maintaining a potential reference. This makes polarization prone to occur during the reaction, leading to working potential drift and reduced measurement accuracy.

The innovation of the three-electrode system lies in the introduction of a reference electrode (RE), forming a complete three-electrode system:

Working electrode (WE): The site of the gas electrochemical reaction, outputting the detection current.

Counter electrode (CE): Provides a pathway for electron transfer, completing the current loop.

Reference electrode (RE): Establishes a stable potential baseline, maintaining a constant potential at the working electrode.

The core value of this design lies in the potentiostat circuit, which continuously monitors the potential difference between the working and reference electrodes and dynamically adjusts the voltage between the two electrodes to ensure that the working electrode potential remains constant relative to the reference electrode. This design effectively eliminates measurement errors caused by counter electrode polarization, electrolyte concentration changes, and temperature fluctuations, significantly improving the accuracy, stability, and service life of the sensor.

Key Technical Elements and Performance Indicators

Key performance indicators include:

Sensitivity (nA/ppm)

Detection range (ppm to percentage level)

Response time (T90)

Selectivity (cross-interference resistance)

Long-term stability (signal drift rate)

Operating life (typically 2-3 years)

Applications and Technical Limitations

Three-electrode electrochemical sensors have been widely used in:

Industrial safety monitoring: Detection of toxic and hazardous gases in hazardous environments such as petrochemicals and coal mines

Ambient air quality monitoring: Monitoring of atmospheric pollutants such as SO₂, NO₂, and O₃

Indoor air quality management: Monitoring of CO₂, VO₃, and CO₂ Detection of Cs, etc.

Medical diagnostic equipment: Breath gas analysis

Automotive electronics: In-vehicle air quality monitoring

Future Development Trends

With technological advancements, three-electrode electrochemical sensors are developing in the following directions:

Miniaturization and integration: Using MEMS technology to manufacture miniature sensors

Intelligence: Integrating temperature compensation, digital output, and self-diagnostic functions

Multifunctionality: Developing sensor arrays capable of simultaneous detection of multiple gases

Long-life design: Improving electrolyte systems and sealing technologies

As a mature and reliable gas detection technology, three-electrode electrochemical gas sensors will continue to play an important role in various fields for the foreseeable future. Through continuous technological innovation and improvement, their performance will be further enhanced and their application will continue to expand, providing solid technical support for creating a safer and healthier living environment for mankind.