News

News Industry News

Industry News In the field of industrial safety and environmental monitoring, combustible gas detection has always been a crucial technical task. Hydrogen, as a clean energy source and an important industrial raw material, makes leak detection particularly critical. Tensensor's ZC2529 catalytic combustion gas sensor, with its stable performance, rapid response, and excellent selectivity, has become the preferred solution for hydrogen and other combustible gas detection.

Core Technology: Catalytic Combustion Principle

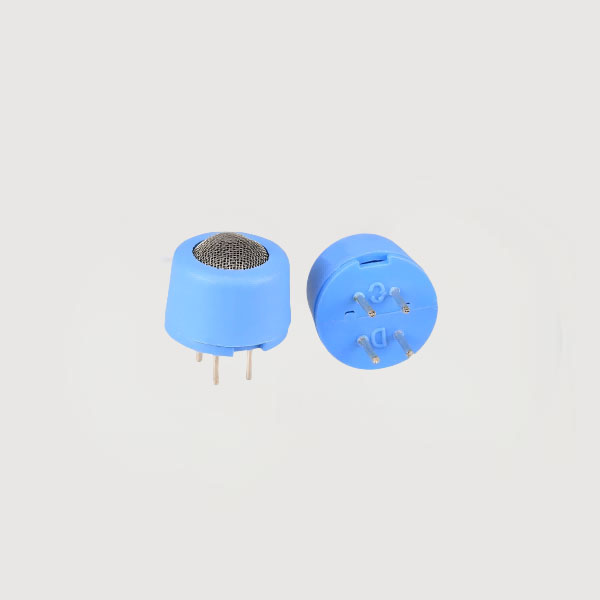

ZC2529 Catalytic Flammable Gas Sensor

The ZC2529 sensor is designed based on the catalytic combustion effect, employing a bridge structure composed of paired detection and compensation elements. When combustible gases such as hydrogen come into contact with the sensor, a catalytic combustion reaction occurs on the surface of the detection element, leading to an increase in resistance and a corresponding change in the bridge output voltage. This voltage change is directly proportional to the gas concentration, enabling accurate measurement. The compensation element serves as a reference and provides temperature and humidity compensation, effectively improving the sensor's stability and accuracy in complex environments.

Product Features and Performance Advantages

Linear Output, Rapid Response: The sensor output voltage exhibits a good linear relationship with gas concentration, with a response time ≤10 seconds and a recovery time ≤30 seconds, suitable for real-time monitoring and rapid alarm scenarios.

High Stability, Strong Anti-interference: Possesses excellent repeatability and long-term stability, with good resistance to common interfering substances such as hydrogen sulfide and organosilicon.

Wide Temperature Range, Strong Adaptability: Operating temperature range -40℃~+70℃, suitable for various scenarios such as industrial sites, warehouse environments, and laboratories.

Moderate Sensitivity, Comprehensive Coverage: Demonstrates good detection capabilities for hydrogen, acetylene, gasoline, and various organic vapors, with a measurement range covering 0~100% LEL.

Main Application Areas

The ZC2529 sensor is widely applicable to the following scenarios:

Hydrogen Energy Systems: Leakage monitoring in hydrogen fuel cells, hydrogen storage and transportation facilities, hydrogen refueling stations, etc.

Chemical and Petrochemical Industries: Leakage detection of organic vapors such as acetylene, benzene, and alcohols/ketones.

Industrial Safety Protection: Monitoring and alarming of combustible gas concentrations in oil and gas pipelines, tank farms, production workshops, etc.

Environmental Monitoring and Laboratories: Detection of volatile organic compounds (VOCs) and gas analysis in scientific research experiments.

Usage Recommendations and Precautions

Avoid contact with silicon compounds, corrosive gases, and environments with condensation.

Strictly control the power supply voltage within the range of 2.5±0.1V to avoid damage from overvoltage.

Store in a clean, dry, silicone-free, sealed environment. If not used for an extended period, perform an aging process with electrical current applied.

Use a low-temperature constant-temperature soldering iron (≤350℃) for soldering, and the soldering time should not exceed 5 seconds to protect the integrity of the sensor structure.

The C2529 catalytic combustion gas sensor, with its reliable technology, stable output performance, and wide application adaptability, provides an efficient and economical solution for industrial gas detection. Whether in new energy facilities, chemical safety, or environmental monitoring, it plays an excellent role in detection and early warning, making it an important tool for promoting safe production and green monitoring. For more technical details or to obtain samples for testing, please contact:

Web: www.tensensor.com

Email: [email protected]

WhatsApp: +86 18335818384