News

News Industry News

Industry News1. The core role of oxygen sensors

Oxygen sensors (O₂ Sensors) are used to detect the oxygen concentration in the environment in real time, and are mainly used in:

Industrial safety: monitoring the oxygen deficiency or oxygen enrichment state of confined spaces (such as mines and storage tanks) to prevent explosion or suffocation risks.

Medical field: monitoring oxygen concentration in ventilators and anesthesia machines to ensure patient safety.

Environmental protection and combustion control: optimizing the air-fuel ratio of boilers and automobile engines to reduce pollutant emissions.

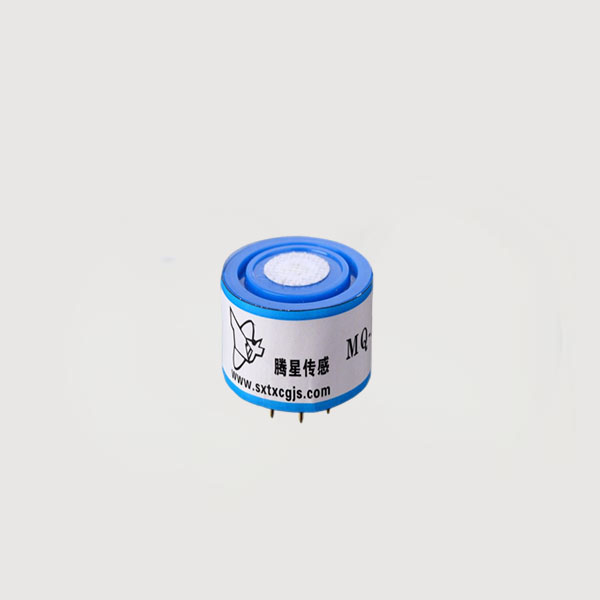

MQ-E2-O2-φ20 Electrochemical O2 Sensor

2. Working principle of mainstream oxygen sensors

Based on the technical principle, oxygen sensors are mainly divided into the following three categories:

① Electrochemical oxygen sensor

Principle: Use redox reaction to generate current signal.

The electrolyte in the sensor (such as KOH) reacts with oxygen:

O₂ + 4e⁻ → 2O²⁻ (cathode)

Pb + 2O²⁻ → PbO₂ + 4e⁻ (anode)

The current generated by the reaction is proportional to the oxygen concentration and is converted into a concentration value through the circuit.

Features:

High sensitivity, suitable for low concentration detection (0~25%).

The electrolyte needs to be replaced regularly, and the service life is usually 1~3 years.

② Zirconia (ZrO₂) oxygen sensor

Principle: Based on the oxygen ion conductivity characteristics of solid electrolyte (zirconia).

At high temperatures (above 650°C), the oxygen concentration difference on both sides of the zirconia will produce a potential difference (Nernst effect):

E = (RT/4F) ln(P₁/P₂)

(R: gas constant, T: temperature, F: Faraday constant, P₁/P₂: oxygen partial pressure ratio)

Calculate the oxygen concentration by measuring the potential difference.

Features:

High temperature resistance, suitable for combustion control (such as automobile exhaust detection).

No electrolyte is required, long life, but high heating power consumption.

③ Optical (fluorescence quenching) oxygen sensor

Principle: Utilize the quenching effect of oxygen on specific fluorescence.

The fluorescent substance in the sensor is excited and emits light, and the oxygen molecules will collide and quench part of the fluorescence.

The oxygen concentration is inferred by detecting the fluorescence intensity or the degree of life decay.

Features:

No consumable parts, life of up to 5~10 years.

Strong anti-interference, suitable for medical or high humidity environments.

3. How to choose a suitable oxygen sensor?

| Type | Applicable scenarios | Advantages | Limitations |

| Electrochemical | Industrial safety, portable detector | Low cost, high sensitivity | Short lifespan, requires maintenance |

| Zirconia (ZrO₂) | High temperature combustion control, automobile exhaust | High temperature resistance, fast response | High power consumption, preheating required |

| Optical | Medical and laboratory precision monitoring | No consumables, long-term stability | Higher cost |

4. Our technical advantages

As a professional gas sensor manufacturer, we provide:

Full range of oxygen sensors: covering electrochemical, zirconium oxide, optical technology, adapted to different needs.

Customized solutions: optimized design for special scenarios such as high temperature and corrosive environment.

Precise calibration service: ensure that the factory sensors meet international standards such as ISO and FDA.

If there are any needs of our products, pls feel free to contact us for more solutions!

Web: www.tensensor.com

Tel/WhatsApp: +86 18335818384

Email: [email protected]