Products

Products CO2 Sensor

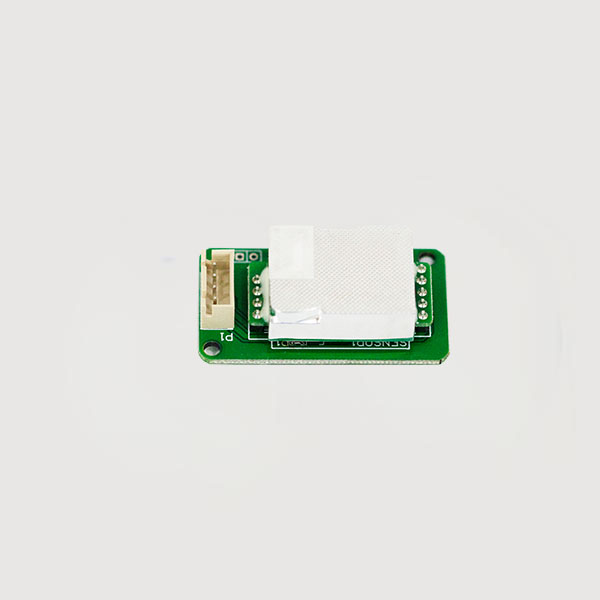

CO2 Sensor

Detect CO2 in the air using the non-dispersive infrared (NDIR) principle

Application:

Smart HomeProduct characteristics:

High sensitivity, low power consumptionDescription

TX-Z19D carbon dioxide gas sensor (hereinafter referred to as sensor) is a general intelligent small sensor, which uses the principle of non-dispersive infrared (NDIR) to detect CO2 in the air. It has good selectivity, no oxygen dependence, long life, etc.; built-in temperature compensation; serial port output, PWM output, easy to use. This sensor is a high-performance sensor made by combining mature infrared absorption gas detection technology with precise optical path design and excellent circuit design.

Specifications

| Product model | TX-Z19D |

| Detection gas | CO2 |

| Supply voltage | DC(5.0±0.1)V |

| Average current | <40mA(@5V power supply) |

| Peak current | 125mA(@5V power supply) |

| Interface level | 3.3V(Compatible with 5V) |

| Detection range | 400~10000ppm(optional, see as follows) |

| Output signal | UART(TTL level, 3.3V) PWM |

| Warm-up time | 1 min |

| Response time | T90<120s |

| Working temperature | 0~50℃ |

| Working humidity | 0~95%RH(no condensation) |

| Storage temperature | -20~60℃ |

| Weight | 5 g |

| Lifespan | >5 years |

Common range and accuracy

| Gas name | Molecular formula | Detection range | Resolution | Accuracy |

| carbon dioxide | CO2 | 400-2000ppm | 1ppm | ±(50ppm+5% reading value) |

| 400-5000ppm | ||||

| 400-10000ppm |

Request Consultation