Products

Products H2 Sensor

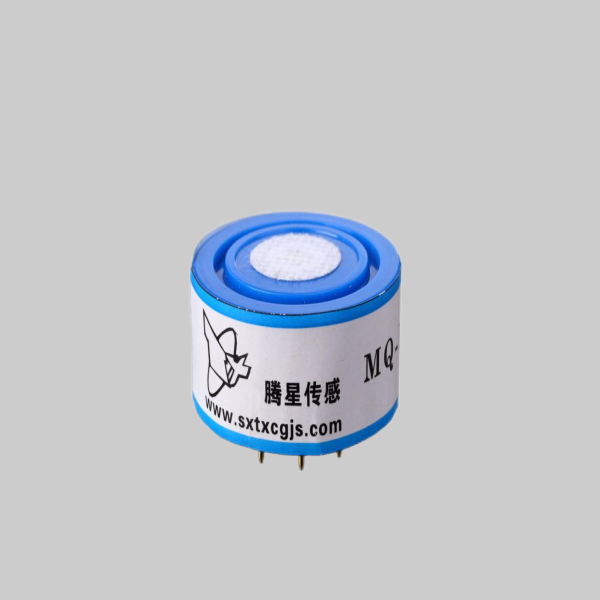

H2 Sensor

Application:

Widely used in commercial, especially civil fields, for hydrogen concentration detectionProduct characteristics:

Low power consumptionDescription

MQ-E2-H2 hydrogen sensor is a fuel cell type sensor. Hydrogen and oxygen undergo corresponding oxidation-reduction reactions on the working electrode and the counter electrode and release charges to form current. The magnitude of the generated current is proportional to the hydrogen concentration and follows Faraday's law. The hydrogen concentration can be determined by measuring the magnitude of the current.

Technical specifications

| Product model | MQ-E2-H2 |

| Detection gas | Hydrogen(H2) |

| Range | 0~30000ppm |

| Max range | 40000ppm |

| Sensitivity | (2±1) nA/ppm |

| Resolution | 50ppm |

| Response time(T90) | <30S |

| Load resistance(recommend) | 200Ω |

| Repeatability | <3% output |

| Stability(/year) | <10% |

| Output linearity | linear |

| Zero drift(-40℃~90℃) | ≤100ppm |

| Temperature range | -20℃~50℃ |

| Pressure range | Standard atmospheric pressure ±10% |

| Humidity range | 15%~90% RH |

| Life | 3 years |

Basic Circuit

Sensor Characterization

TenSensor, China's first listed gas sensor company,Tensensor can provide more than 100 varieties of six series including:

semiconductor gas sensor

electrochemical gas sensor

infrared gas sensor

dust sensor

pyroelectric sensor

thermopile sensor, etc.

which can be used for more than 200 kinds of gas and infrared, dust and other indicators detection, widely used in the field of security for detecting gas leakage, noxious gas leakage, smog and fire, the field of family, office and factory for detecting HCHO, VOC, CO2, PM2.5 and so on.

Moreover, the solutions for security, household electrical appliances, consumer electronics, smart home, instruments and meters are available.

For more information about MQ-E2-H2 sensor, please contact account manager.

TEL:0086-0351-5249552

Whatsapp:+86 18335818384

Email:[email protected]

Request Consultation