Products

Products Temperature and humidity sensor

Temperature and humidity sensor

Application:

Non-contact temperature measurementProduct characteristics:

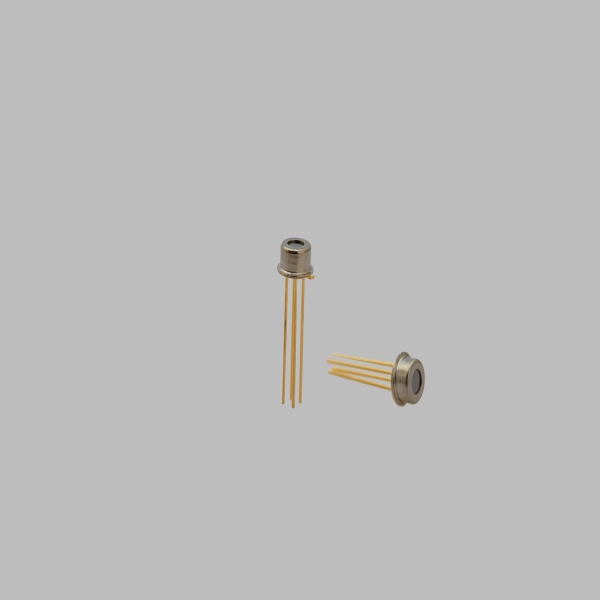

TO-46 metal package1. Description

The GT-511 sensor is a thermopile temperature sensor, which is made of hundreds of pairs of thermocouples connected in series based on MEMS technology. Using the Seebeck principle, when there is a temperature difference between the target and the environment, the sensor outputs a corresponding voltage, thereby detecting the presence of the target or the temperature of the target.

2. Appearance and dimension

3. Technical specifications

| Parameter | Value | Unit | Remarks |

| Sensitive area | 1.6*1.6 | mm | |

| Field of view | 105 | Degree | Above 50% |

| Thermopile resistor | 120±30 | KΩ | 25℃ |

| Noise voltage | 45 | nV/Hz1/2 | 25℃ |

| Noise equivalent power | 0.27 | nW/Hz1/2 | 500K,1Hz,25℃ |

| Response rate | 124 | V/W | 500K,1Hz,25℃ |

| Time constant | 10 | ms | |

| Detection rate | 1.0*108 | cmHzl/2/W | 500K,1Hz,25℃ |

| NTC resistance | 100±1% | KΩ | 25℃ |

| NTC (β) | 3950±1% | / | 25℃/50℃ |

| operating temperature | -35~125 |

4. Recommend Circuit

5.Sensor Features:

1.Thermopile performance (V-T) curve: Test conditions: 25℃, TO-46 package, LWP5.5 filter;

2. Filter performance curve: wavelength range, 5.5~ 14μm; 5.5~ 14μm, average transmittance ≥ 75%; below 5μm, transmittance < 1%;

6.How to use:

1. Read the resistance value Ra of the thermopile temperature sensor pins 2 and 4;

2. Find the corresponding ambient temperature Ta according to Ra in the R-T table in the specification;

3. Read the voltage Va of the sensor pins 1 and 3;

4. Find the voltage value equal to or close to the Va value in the Ta column of the V-T table, and the corresponding Tobj row is the temperature Tobj of the object being measured.

7.Notes:

The sensor must first calibrate the resistance of the thermistor NTC;

The sensor test is affected by factors such as black body temperature, distance, and environment. The V-T meter is for reference only and needs to be calibrated before use;

The output voltage of the sensor test is easily affected by the NTC resistance. It is necessary to increase the thermal resistance and heat capacity to increase the temperature stability. Generally, metal (copper, aluminum) kits are used;

In order to reduce the thermal interference between the sensor pins, the sensor pins should be thermally isolated when making PCB

The manual welding temperature is 330±20℃, and the welding time of a single pin does not exceed 3s;

Frequent, excessive vibration, strong impact or collision will cause resonance inside the sensor and break.

Request Consultation