Products

Products Catalytic Combustion Gas Sensor

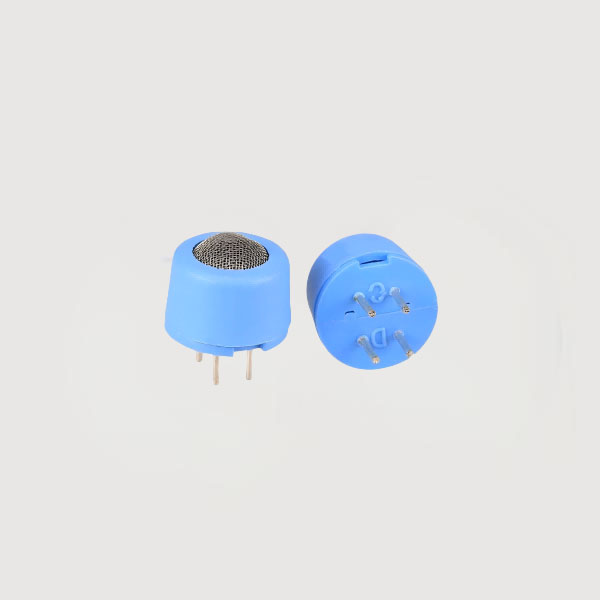

Catalytic Combustion Gas Sensor

Application:

It is widely used in industrial occasion to detect the concentration of hydrogen, ethyne, gasoline, VOC such as alcohol, ketone, benzene.Product characteristics:

The bridge output is linearDescription

ZC2529 adopts catalytic combustion principle, and its two arms of electric bridge consists of a test element and a compensate element. The resistance of the test element rises once it meets the combustible gases, in the same time, the output voltage of the bridge changes and the voltage variation rises in direct proportion to the gas concentration. The compensate element, as a conference, has the function of compensating temperature and humidity.

Specifications

Model | ZC2529 |

Sensor type | Catalytic |

Standard encapsulation | Plastic encapsulation |

Working voltage(V) | 2.5±0.1 |

Working current(mA) | 100±10 |

Sensitivity(mV) | 1% H2: 20~50 1% C2H2:40~90 |

Linearity | ≤5% |

Measuting range(%LEL) | 0~100 |

Response time(90%) | ≤10s |

Recovery time(90%) | ≤30s |

Working environment | -40~70℃,less than 95% RH |

Storage environment | -25~70℃,less than 95% RH |

Lifespan | 2 years |

Request Consultation