Products

Products CH2O Sensor

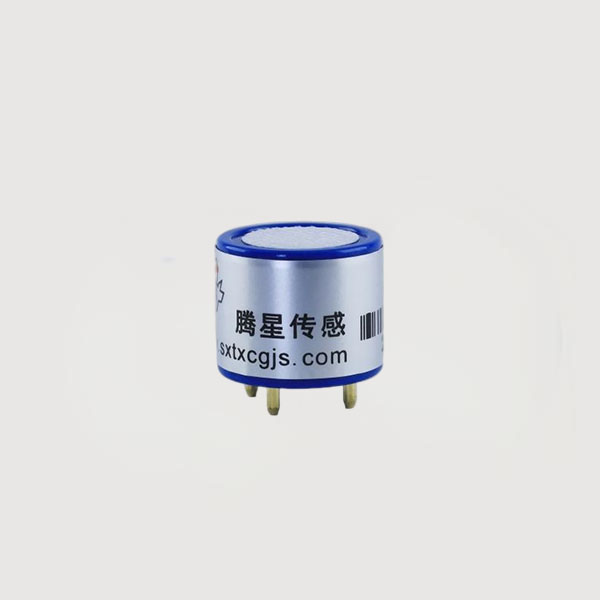

CH2O Sensor

Application:

Used for formaldehyde detection in industrial and environmental protection fieldsProduct characteristics:

Low power consumptionDescription

MQ-E3-CH2O formaldehyde sensor is a constant potential electrolytic sensor. Formaldehyde and oxygen undergo corresponding redox reactions on the working electrode and the counter electrode and release charges to form current. The magnitude of the current generated is proportional to the concentration of formaldehyde. The formaldehyde concentration can be determined by testing the magnitude of the current.

Specifications

| Product model | MQ-E3-CH2O |

| Detection gas | CH2O |

| Range | 0~10ppm |

| Max Range | 100ppm |

| Sensitivity | (11.8±6)µA/ppm |

| Resolution | 0.1ppm |

| Response time(T90) | ≤90S |

| Bias voltage | 300mV |

| Load resistance(recommend) | 10Ω |

| Repeatability | <2% output data |

| Stability(/month) | <2% |

| Output linearity | Linear |

| Zero drift(-20℃~40℃) | -0.03ppm~0.03ppm |

| Temperature range | -20~50℃ |

| Humidity range | 15%~90% RH(No condensation) |

| Pressure range | Standard atmospheric pressure ±10% |

| Usage Life | 2 years(in air) |

Request Consultation