Products

Products CO2 Sensor

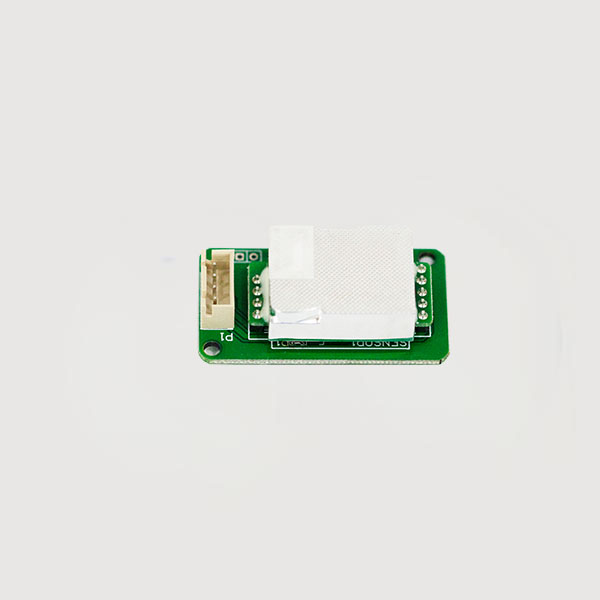

CO2 Sensor

Detection of CO2 in Air Using Non Dispersive Infrared (NDIR) Principle

Application:

Heating, Ventilation, and Refrigeration EquipmentProduct characteristics:

High sensitivity, low power consumptionDescription

The TX-Z19E carbon dioxide gas sensor (hereinafter referred to as the sensor) is a universal intelligent small sensor with two products: pins and terminals. It uses the principle of non dispersive infrared (NDIR) to detect CO2 in the air, and has the characteristics of good selectivity, oxygen independence, and long service life; Built in temperature compensation; Simultaneously equipped with serial port output and PWM output, convenient to use. This sensor is a high-performance sensor that combines mature infrared absorption gas detection technology with precision optical path design and sophisticated circuit design.

Specifications

| Product model | TX-Z19E |

| Detection gas | CO2 |

| Working voltage | 5.0±0.1V DC |

| Average current | <40mA(@5V power supply) |

| Peak current | 125mA(@5V power supply) |

| Interface level | 3.3V(Compatible with 5V) |

| Detection range | 400~10000ppm(optional, see as follows) |

| Output signal | Serial port(UART)(TTL level 3.3V) PWM |

| Preheat time | 1 min |

| Refresh time | 2 s |

| Response time | T90<120s |

| Working temperature | -10~50℃ |

| Working humidity | 0~95%RH(no condensation) |

| Storage temperature | -20~60℃ |

| Weight | 5 g |

| Lifespan | >10 years |

Common range and accuracy:

| Gas name | Molecular formula | Range | Resolution | Accuracy |

| Carbon dioxide | CO2 | 400~2000ppm | 1ppm | ±(50ppm+5% reading value) |

| 400~5000ppm | ||||

| 400~10000ppm |

Request Consultation