News

News Industry News

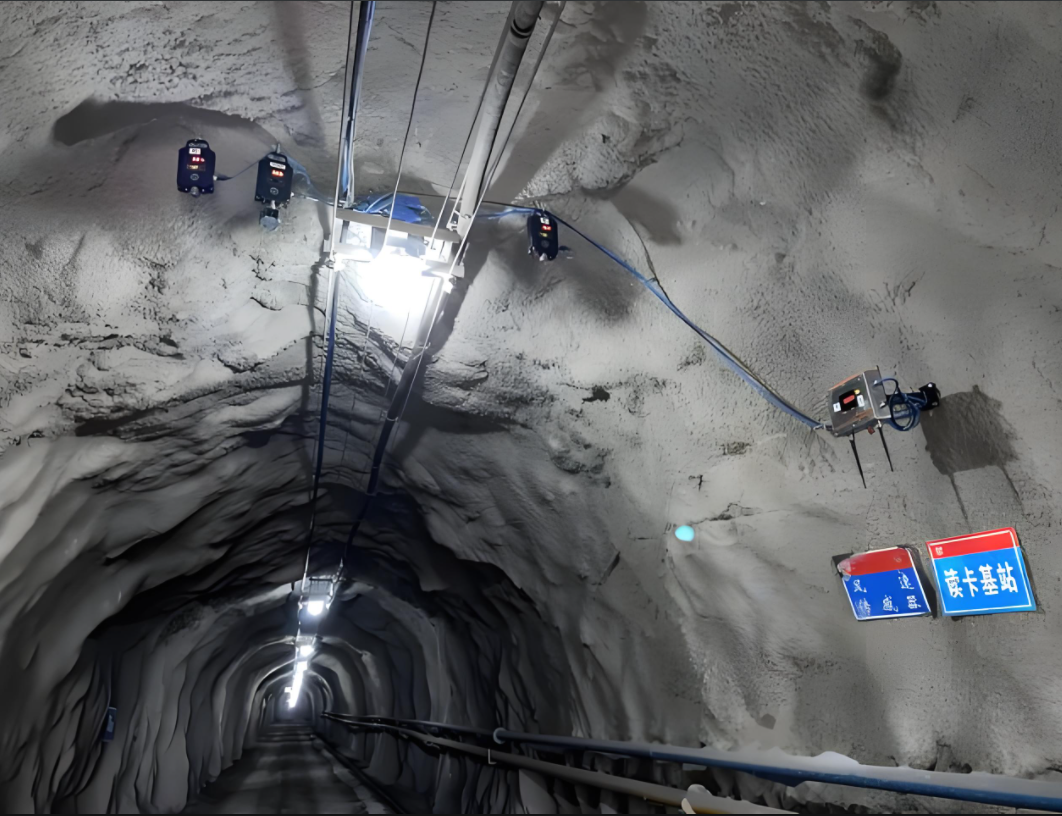

Industry NewsCoal Mine Safety Starts with "Precise Sensing"

Hello everyone, we are Tensensor, a company specializing in gas sensors for 40 years. Let's discuss the core equipment for underground mine safety—the coal mine laser methane sensor.

In coal mining, gas explosions are always a constant threat. As the primary component of methane, accurate, real-time monitoring of its concentration is crucial for accident prevention. While widely used, traditional catalytic combustion sensors suffer from persistent drawbacks such as susceptibility to poisoning, high false alarm rates, and frequent calibration.

Shanxi Tengxing Sensing Technology Co., Ltd. has been deeply engaged in the gas sensing field for 40 years, committed to applying advanced technologies to safe production. We will provide an in-depth analysis of the working principles of this next-generation safety guardian—the mine laser methane sensor—to see how it discerns risks with its eagle-eyed insight, revolutionizing mine safety.

Core Principle: TDLAS Technology - A "Specialized Physical Examination" for Methane Molecules

The core technology of the mining laser methane sensor is tunable diode laser absorption spectroscopy (TDLAS). You can think of it as a specialized "laser flashlight."

Emitting a Specific Laser: The sensor emits a laser beam with a precisely tuned wavelength that is specifically "favored" and absorbed by methane molecules. In other words, this beam is "customized" specifically for methane molecules.

Traversing the Detection Area: This specific laser beam passes through the gas region to be measured. If methane is present in the environment, the methane molecules actively "devour" (absorb) some of the laser energy.

Receiving and Analyzing: A detector at the other end of the sensor receives the laser signal after it has passed through the gas. By precisely calculating the intensity attenuation after absorption, the specific methane concentration can be directly and accurately calculated.

This process is like "molecular fingerprinting." Each gas molecule has its own unique absorption spectrum (like a human fingerprint). The laser methane sensor achieves highly selective detection of methane by identifying its "molecular fingerprint" with almost no interference from other gases.

Disruptive Advantages: Why is Laser Methane a Superior Solution?

Compared to traditional sensors, laser methane sensors offer overwhelming advantages:

Anti-interference: Response only to methane, completely eliminating "poisoning" and false alarms caused by other gases in the well (such as hydrogen sulfide and silane).

Unparalleled Accuracy: Measurements are stable and reliable, with extremely high accuracy and minimal error, providing reliable data support for safe production decisions.

No Frequent Calibration Required: Based on the principles of physical optics, there is no wear and tear on chemical catalytic components, resulting in a longer service life and significantly reduced maintenance costs and manpower.

Extremely Fast Response: Real-time, continuous monitoring is achieved. If concentrations exceed the specified limit, an alarm is issued instantly, saving valuable time for evacuation and emergency response.

Intrinsically Safe: Using non-contact optical detection, there is no need to ignite the gas within the detection chamber, fundamentally eliminating the risk of ignition or explosion.

Product Recommendation

XH-ID-04-01 4-series laser methane sensor probe

Parameter | Mix values | Typical values | Max values | Unit | ||

General parameters | ||||||

Storage temperature | -40 | —— | 85 | ℃ | ||

Operating temperature | 82010521-04 | -20 | —— | 60 | ℃ | |

82010521-05 | —— | |||||

82010521-06 | -40 | —— | 70 | |||

82010521-07 | —— | |||||

Operating humidity (non-condensing) | —— | —— | 98 | %RH | ||

Working pressure | 80 | —— | 116 | kPa | ||

Detection range | 0 | —— | 100 | %LEL | ||

Basic error | normal temperature | ±3 | %LEL | |||

full temperature | ±5 | %LEL | ||||

Detection limit | 1000 | ppm | ||||

Minimum resolution | 0.01 | %vol | ||||

Communication interface | ||||||

TTL | Baud rate | —— | 9600 | —— | baud | |

Stop bit | —— | 1 | —— | Bit | ||

Data bit | 8 | —— | Bit | |||

Parity bit | —— | —— | Bit | |||

Flow control bit | —— | —— | —— | Bit | ||

Electrical properties (room temperature) | ||||||

Operating voltage | 3.3 | 3.6 | 50 | V | ||

Operating current (average) | —— | —— | —— | mA | ||

Operating current (instantaneous) | —— | 250 | 320 | mA | ||

Size | ||||||

Size | Φ20 x 16 (Length 4.9mm excluding pins) | mm | ||||

Filter method | 82010521-04 | Filter with waterproof breathable membrane | —— | |||

82010521-05 | Filter | —— | ||||

82010521-06 | Filter with waterproof breathable membrane | —— | ||||

82010521-07 | Filter | —— | ||||

XH-ID-01 Integrated point laser methane probe

Parameter | Mix values | Typical values | Max values | Unit | ||

General parameters | ||||||

Storage temperature | -40 | —— | 85 | ℃ | ||

Operating temperature | 82010521-04 | -10 | —— | 50 | ℃ | |

82010521-05 | —— | |||||

82010521-06 | -40 | —— | 70 | |||

82010521-07 | —— | |||||

Operating humidity (non-condensing) | —— | —— | 98 | %RH | ||

Working pressure | 80 | —— | 116 | kPa | ||

Detection range | 0 | —— | 100 | %vol | ||

Basic error | 0-1.00%vol | ±600ppm | —— | |||

(1.00~100)%vol | True value±6% | —— | ||||

Response time | - | 15 | - | s | ||

0.01 | %vol | |||||

Communication interface | ||||||

TTL | Baud rate | —— | 9600 | —— | baud | |

Stop bit | —— | 1 | —— | Bit | ||

Data bit | —— | 8 | —— | Bit | ||

Calibration bit | —— | —— | —— | Bit | ||

Electrical properties (room temperature) | ||||||

Operating voltage | 3.3 | 3.6 | 50 | V | ||

Operating current (average) | —— | 30 | —— | mA | ||

Operating current (instantaneous) | —— | 250 | 320 | mA | ||

Size | ||||||

Diameter* long | Φ39.3 x 54.3(Not including matching parts) | mm | ||||

Safety is the cornerstone of coal mining operations. Investing in more advanced and reliable monitoring technology is a responsible choice for the future of the company and the lives of miners. Laser methane sensors, with their undeniable technological advantages, are becoming a standard feature of modern intelligent mine construction. At Tensensor, we are committed to becoming your trusted safety partner, leveraging our four decades of expertise and dedication. Let us illuminate the path to safety in every mine with the light of technology.