News

News Industry News

Industry News Gas safety is a crucial factor affecting the safe operation of cities. As major users of gas, restaurants are densely populated areas with significant safety responsibilities; gas accidents can easily cause substantial casualties. Therefore, preventing gas leaks and ensuring safe gas usage is an indispensable and essential lesson for catering businesses.

The core function of a combustible gas alarm device is the real-time monitoring and alarming of combustible gas leaks. The quality of the gas sensor used directly affects the overall performance.

In alarms used in industrial and commercial sectors, catalytic combustion gas sensors are typically employed to monitor leaks of combustible gases such as natural gas, liquefied petroleum gas (LPG), and coal gas.

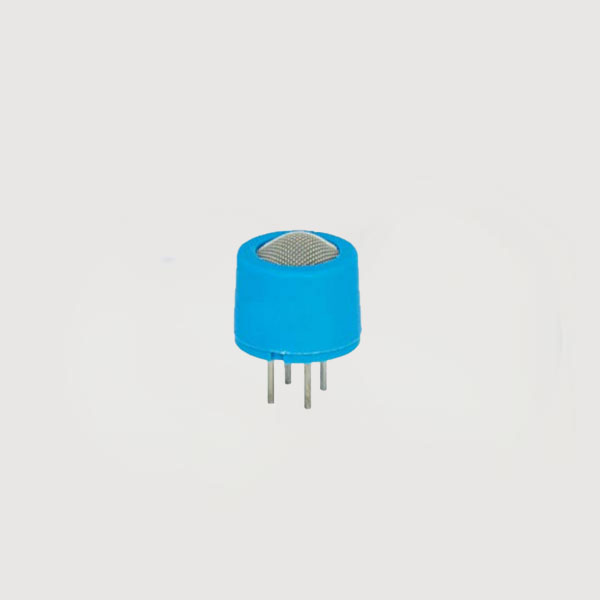

ZC25A Catalytic Combustion Gas Sensor

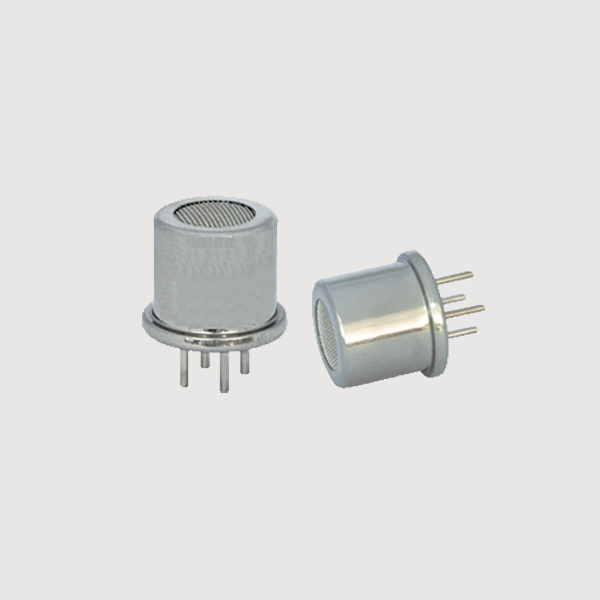

ZC25D Catalytic Combustion Type Gas Sensor

Principle Introduction

The catalytic combustion gas sensor utilizes the thermal effect of catalytic combustion. It consists of a detection element and a compensation element paired to form a measuring bridge. Under certain temperature conditions, combustible gas undergoes flameless combustion on the surface of the detection element carrier and under the action of a catalyst. This increases the carrier temperature, consequently increasing the resistance of the platinum wire inside, thus unbalancing the bridge and outputting an electrical signal proportional to the concentration of the combustible gas.

Sensor Features

Catalytic combustion gas sensors are currently the most widely used sensors in the world. They have a fast response speed, and up to the lower explosive limit (LEL), the sensor output is almost directly proportional to the gas concentration. Therefore, they have high accuracy and repeatability, making them suitable for detecting the concentration of combustible gases such as industrial and commercial fuel gas, liquefied petroleum gas, coal gas, and alkanes.

Alarm devices using catalytic combustion gas sensors as detection elements require precautions against substances that can poison the sensor, such as silicon compounds, lead compounds, halogenated hydrocarbons, sulfides, and phosphides. They should also be protected against high-concentration gas environments exceeding the detection range and mechanical impacts to prevent damage to the sensor's performance and consequently, the overall performance of the alarm device.

There are many types of gas sensors used for combustible gas detection, including semiconductor, catalytic combustion, electrochemical, and infrared types. Catalytic combustion gas sensors, due to their characteristics, are more suitable for detecting flammable and explosive gases or organic vapors within the lower explosive limit concentration range in industrial, coal mining, and civilian applications. For more combustible gas detection solutions, please contact Tensensor:

Website: www.tensensor.com

Email: [email protected]

WhatsApp: +86 18335818384